Project Description

Project Details

In 2009 the Dublin VA Medical Center in Georgia contracted Harrell Design Group, PC to provide A/E services for the design and construction of an in-patient medical ward renovation. At that time, design of a new air handling unit to serve the renovated ward was being handled by another firm. Shortly after beginning programming, HDG reviewed the proposed AHU design and expressed concern over placement of the new unit in the existing attic. At no cost to the VA, HDG conducted structural evaluation of the existing attic floor (including laboratory testing of concrete core samples) and determined that it could not support the proposed AHU. The VA asked HDG to takeover design of the new AHU and associated ductwork.

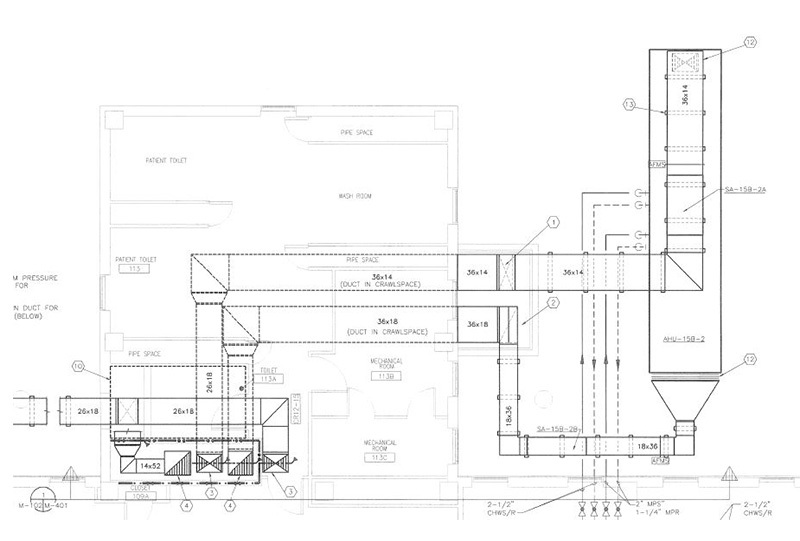

The final design included two new air-handling units located in a new mechanical yard adjacent to the renovated medical ward. One of the greatest challenges on this project was coordination of new ductwork with the existing structural system. It was discovered that existing concrete floor beams at the first floor, second floor, and attic were not aligned. New ductwork required more bends than would be typical in new construction. Duct bends, sizing, turning vanes, and access doors were carefully considered to make sure that static pressure is as low as possible, noise is minimized, and VA engineering staff have easy access to fire dampers and turning vanes.

Another challenge occurred during construction when it was discovered that the units were not performing in accordance with the specifications. Again, at no cost to the VA, HDG made numerous trips to the project site to evaluate the test and balance reports and to observe system operation. It was determined that the unit was not installed with the correct fans. They were not as specified or as submitted. On behalf of the VA, HDG worked with the manufacturer to replace the fans, re-start the units, and evaluate new test and balance data.

Project Cost: $4,200,000