Project Details

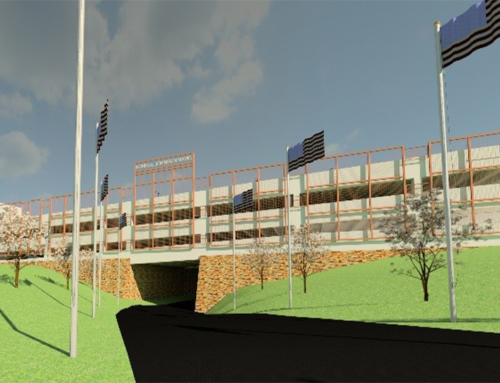

The Salem VA Medical Center is presently served by a central steam plant which was constructed in the 1939. The project scope of work included a new campus infrastructure master plan which incorporated a full evaluation of the existing underground steam distribution system, including the pump condensate return system. Although the central boilers and related plant equipment have been replaced once, they have now exceeded their useful lives. The age of the existing building severely limits options for renovations.

Harrell Design Group conducted a study to identify options for upgrading the existing plant. Following completion of the study, the VA concluded that the best option was to replace the existing plant with a new building. This new plant will include (2) 500 BHP water tube boilers and (1) 250 BHP water tube boiler. All boilers will be dual fuel natural gas/fuel oil. The facility will be fully backed-up with a new diesel fuel emergency generator. Stand by fuel tanks will be provided on-site for (10) days of normal operations following a utility interruption. The boiler plant will be constructed near the existing boiler plant and the existing plant will be decommissioned. The new building will be designed to be expanded to accommodate a new chiller plant.

The project scope of work included a new 500 foot-long ten-foot-wide by ten-foot-high underground steam distribution tunnel to connect the new steam system to the existing steam and condensate return systems. The facility design also incorporates a new fully redundant PLC controls system for boiler burner control, make-up water, and steam boiler control. System status is displayed on a graphics-based 42” touch screen monitor located within full view of boilers and the firing aisle. The project incorporates the new energy control center (ECC). The ECC design includes monitoring of all critical energy management, emergency generators, medical gas system, pneumatic tube system and fire alarm systems. Power transfer from emergency source is provided using closed transition bypass isolation automatic transfer switches.

Project Size: 11,500 SF

Project Cost: $8,900,000